Workpiece size (mm):

ID: 35~63

OD: 32~112

Length: 220~600

Workpiece material: 38CrMoAl

Advanced nitrided steel with high wear resistance, high fatigue strength and high strength. It is mainly used for nitrided parts with accurate dimensions after heat treatment, or various nitrided parts with high wear resistance which are not subject to high impact loads, such as boring bars, spindles of grinding machines, spindles of automatic lathes, worm gears, precision wire rods, precision gears, high-pressure valves, valve stems, gauges, samples, rollers, imitation moulds, cylinder bodies, piston rods of compressors, speed governors, rotating bushings, fixed bushings of turbines, various wear-resistant parts of rubber and plastic extruders, and so on. etc.

Chemical composition:

Carbon C :0.35~0.42

38CrMoAl alloy structural steel

Silicon Si: 0.20~0.45

Manganese Mn: 0.30 ~ 0.60

Sulfur S: allowable residual content ≤ 0.035

Phosphorus P : Allowable residual content ≤ 0.035

Chromium Cr:1.35~1.65

Aluminium Al: 0.70~1.10

Nickel Ni: allowed residual content ≤ 0.30

Copper Cu: allow residual content ≤ 0.30

Molybdenum Mo:0.15~0.25

Density of 38CrMoAl:7.85g/cm3

07Х16Н4Б

Corrosion-resistant (stainless) common steel. Description of steel grades: 07 - 7% carbon, X16 - 16% chromium, H4 - 4% nickel, B - guaranteed composition steel (hot worked). The steel belongs to the martensitic group and is used for highly loaded components in the marine mechanical engineering, chemical and nuclear energy, oil and gas production and processing industries.

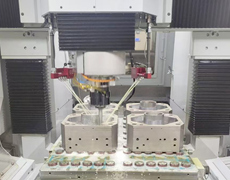

Machining requirements:

Process 1:

From initial finish Ra2.5 to Ra0.4,removal allowance is 0.1mm!

At this time HRC32~36, after nitriding treatment-HRC65~80.

Process 2:

from Ra=0.4, machining to Ra=0.1, the removal allowance is 0.05mm!

Work process 3:

Honing:

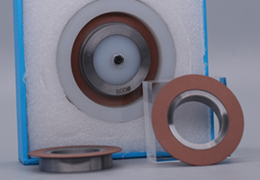

From Ra=0.1,machining to Ra0.063(HRC65~80)

75L*6W*5H-honing bar